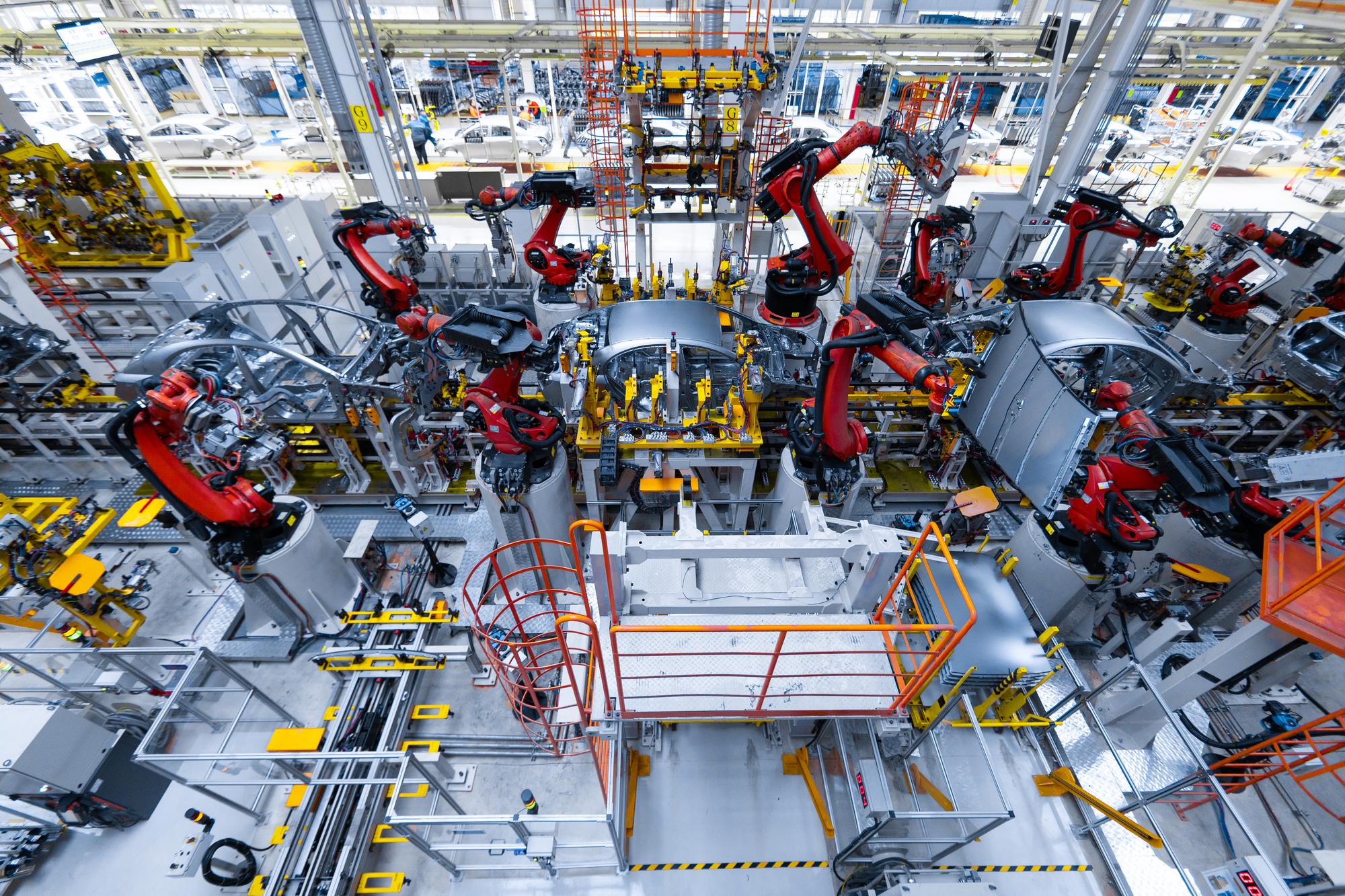

In modern manufacturing, industrial robots play a crucial role, enhancing production efficiency and process control. However, as these complex machines are widely used in industry, related faults and maintenance issues become increasingly prominent. This comprehensive guide provides detailed analysis and diagnosis of several common industrial robot malfunctions, offering corresponding solutions for each, aiming to assist maintenance personnel and engineers in efficiently and safely resolving these issues.

PART 1 Introduction

Industrial robots are indispensable in contemporary manufacturing, improving production efficiency and precision. With the widespread use of these sophisticated devices in industry, associated malfunctions and maintenance challenges have become more apparent. By analyzing typical industrial robot failure cases, we aim to thoroughly address and understand common problems in this field. The following fault case analysis mainly covers core issues such as hardware and data reliability, unconventional robot performance during operation, stability of electric motors and drive components, accuracy of system initialization and configuration, and robot performance in various working environments. Through detailed dissection and handling of some typical failure cases, this guide provides solutions for manufacturers and personnel maintaining robots, helping to extend the actual service life and safety of equipment. Additionally, by identifying faults and their causes from multiple angles, this guide accumulates valuable insights for similar cases, which is crucial for the healthy development of intelligent manufacturing, whether in the current industrial robot domain or for future advancements.

PART 2 Faults and maintenance Cases

2.1 Overspeed Alarm

During actual production, an industrial robot exhibited an overspeed alarm, severely impacting manufacturing. After detailed fault analysis and resolution, the process is as follows: The robot automatically outputs an overspeed alarm and halts during task execution, which may be caused by software tuning, control systems, and sensors, among other factors.

1) Software Configuration and System Diagnosis: Log into the control system to check speed and acceleration parameters. Run system self-diagnostic programs to diagnose potential hardware or software faults. No abnormalities were found in the system’s operational validity and acceleration parameters.

2) Sensor Inspection and Calibration: Inspect the speed and position sensors mounted on the robot. Calibrate sensors using standard tools. Rerun tasks to observe if overspeed warnings persist. Result: A slight reading error was detected in the speed sensor. The problem continued even after recalibration.

3) Sensor Replacement and Comprehensive Testing: Replace the speed sensor with a new one. Conduct a full system self-check and parameter calibration after the replacement. Run various types of tasks to verify if the robot has returned to normal. Result: No further overspeed warnings occurred after the new speed sensor was installed and calibrated.

4) Conclusion and Solution: Combining various diagnostic methods, the main cause of the industrial robot’s overspeed phenomenon was a malfunctioning speed sensor, requiring the replacement and calibration of a new speed sensor.

2.2 Unusual Noises

An industrial robot produced unusual noises during operation, reducing workshop efficiency.

1) Preliminary Inspection: The initial suspicion was mechanical wear or lack of lubrication. Halt the robot to conduct a detailed inspection of mechanical components such as joints, gears, and bearings. Manually move the robotic arm to detect any wear or friction. Result: All joints and gears appeared normal, and lubrication was sufficient, ruling out this possibility.

2) Further Inspection: External Interference or Debris. Thoroughly inspect the robot’s surroundings and movement path for external objects or debris. Clean and sweep each component of the robot. No evidence of external factors was found, ruling out extrinsic factors.

3) Reinspection: Uneven or Overloaded Load. Check the load settings of the robot arm and tools. Compare actual loads with the recommended loads specified in the robot’s manual. Run several load test programs and observe if unusual noises intensify. Result: The noise significantly increased during the load test programs, especially under high loads.

4) Conclusion and Solution: Through on-site detailed testing and analysis, the main cause of the robot’s unusual noises was identified as uneven or excessive load.

Solution: Reconfigure work tasks to ensure even load distribution. Adjust the parameters of the robot arm and tools to accommodate actual loads. Rerun system tests to confirm the resolution of the issue.

The robot’s unusual noise issue was resolved using the above technical means, allowing the equipment to be put back into production.

2.3 Motor Overtemperature Alarm

An industrial robot in testing triggered an alarm due to motor overheating (alarm code: 501-1), which could affect the safe operation of the robot.

1) Preliminary Inspection: The robot’s motor cooling system. Considering the issue of motor overheating, we focused on inspecting the motor’s cooling system.

Procedure: Halt the robot to check if the motor cooling fan operates normally and if the cooling channels are blocked.

Result: The motor cooling fan and cooling channels were normal, ruling out cooling system issues.

2) Further Inspection of Motor and Drive. Issues with the motor or its drive could also cause high temperatures.

Procedure: Check for any damage or loosening in the motor connection wires, conduct surface temperature tests on the motor, and use an oscilloscope to check the current and voltage waveforms from the motor drive.

Result: Unstable current waveforms were observed from the motor drive.

3) Conclusion and Solution. After a series of diagnostic steps, the cause of the robot motor’s high temperature was determined.

Solution: Replace or repair the unstable motor drive. After replacement or repair, rerun system tests to confirm if the issue is resolved. The robot returned to normal operation without further motor overheating alarms after the replacement and testing.

2.4 Initialization Error Diagnosis Alarm

An industrial robot displayed multiple alarms during restart initialization, requiring fault diagnosis to identify the cause.

1) Check External Safety Signals. Initially suspected to be related to abnormal external safety signals. Enter “Operation” mode to determine if there are issues with the robot’s external safety circuits. The robot operates in “on” mode, but the operator still cannot clear the alarm lights, ruling out the loss of safety signals.

2) Software and Driver Check. Check for updates or missing files in the robot’s control software. Verify all drivers, including those for motors and sensors. It was found that the software and drivers were up-to-date with no missing files, so this was not the cause.

3) Identify the fault as originating from the robot’s own control system. In the teach pendant main menu, select “Operation” → “After-Sales Service” → “Operation Mode.” Recheck the alarm messages. Power on the robot, and since the functions did not return to normal, it can be determined that the fault lies within the robot itself.

4) Cable and Connector Inspection. Inspect all cables and connectors connected to the robot. Ensure there is no damage or loosening. All cables and connectors were intact, and the fault was not here.

5) CCU Board Inspection. According to the alarm prompt, locate the SYS-X48 interface on the CCU board. Observe the status lights on the CCU board. The CCU board status lights showed abnormalities, indicating that the CCU board was damaged.

6) Conclusion and Solution. After the above five steps, it was determined that the problem was with the CCU board.

Solution: Replace the damaged CCU board. After the CCU board replacement, the robot system can be used normally, and the initialization error alarm has been resolved.

2.5 Rotary Encoder Data Loss

Upon equipment startup, an industrial robot operator displayed “SMB serial measurement board backup battery lost, robot rotary encoder data lost,” rendering the teach pendant unusable.

Operational errors or human interference are common causes of complex system failures.

1) Pre-fault analysis communication. Inquire whether the robot system has undergone recent maintenance, been serviced by different personnel, or experienced abnormal operations and adjustments.

2) Check system operation records and logs for any activities inconsistent with normal operation modes. No obvious operational errors or human interference were found.

3) Circuit board or hardware failure. Analysis: Since it involves the “SMB serial measurement board,” this is usually directly related to hardware circuits. Disconnect the power and follow all safety procedures. Open the robot control cabinet and inspect the SMB serial measurement board and other related circuits. Use testing tools to check circuit continuity and integrity. Look for obvious physical damage such as burning, breaking, or other abnormalities.

After detailed inspection, the circuit boards and related hardware appeared normal, with no obvious physical damage or connection issues. The possibility of circuit board or hardware failure was low.

4) Backup battery issue. Since the above two aspects seemed normal, other possibilities were considered. The teach pendant clearly mentioned “backup battery lost,” which became the next focus. Locate the specific position of the backup battery in the control cabinet or robot. Check the battery voltage. Inspect the battery interfaces and connections for integrity. The backup battery voltage was significantly lower than normal, with almost no remaining charge. The fault was likely due to the failure of the backup battery.

5) Solution. Purchase a new battery of the same model and specifications as the original, and replace it according to the manufacturer’s instructions. After replacing the battery, initialize and calibrate the system according to the manufacturer’s guidelines to restore lost or damaged data.

After replacing the battery and initializing, conduct a comprehensive system test to ensure the problem has been resolved.

6) After detailed analysis and inspection, initial suspicions of operational errors and circuit board or hardware failures were ruled out, and it was ultimately determined that the problem was caused by the failure of the backup battery. By replacing the backup battery and reinitializing and calibrating the system, the robot returned to normal operation.

PART 3 Daily Faults and maintenance Suggestions

Daily maintenance is key to ensuring the stable operation of industrial robots. The following points should be addressed:

1) RegularCleaning and Lubrication: Regularly inspect key components of the industrial robot, remove dust and foreign objects, and lubricate to ensure normal operation of parts.

2) Sensor Calibration: Regularly calibrate the robot’s sensors to ensure accurate data acquisition and feedback for precise motion and operation.

3) Check and Tighten Bolts and Connectors: Inspect the robot’s bolts and connectors for loosening and tighten them in a timely manner to avoid mechanical vibration and instability.

4) Cable Inspection: Regularly inspect cables for wear, cracks, or breaks to ensure stable signal and power transmission.

5) Spare Parts Inventory: Maintain a stock of key spare parts to replace faulty components promptly in emergencies and reduce downtime.

PART 4 Conclusion

For fault diagnosis and positioning, industrial robot common faults are divided into hardware failure, software failure, and common fault types of robot parts. By summarizing in detail, we can better understand the most common fault types of industrial robots, enabling rapid diagnosis and fault location when they occur, and better maintenance.

As industry moves towards automation and intelligence, industrial robots will become increasingly important. Learning and summarizing are crucial for continuously improving the ability to solve problems and adapt to changing environments. It is hoped that this article will be of reference significance to practitioners in the field of industrial robots, thereby promoting the development of industrial robots and better serving the manufacturing industry.