Introduction to FANUC Robot Operations: Common Instructions Compared with ABB

There are certain differences in the operation and programming methods of robots from different brands, but many programming instructions have similar functionalities. Today, let’s compare some commonly used programming instructions between FANUC and ABB robots.

The introductory series on FANUC robot operations comes to an end today. The previous lessons shared some operational tutorials and manuals, which I believe can resolve some confusions for friends in actual operations.

Comparison of Three Major Motion Instructions

Joint Motion:

FANUC: J ABB: MoveJ

Linear Motion:

FANUC: L ABB: MoveL

Arc Motion:

FANUC: C ABB: MoveC

Instruction Format Comparison:

FANUC

L P[i] Speed CNT ACC100

1) L instruction code

2) P[i] Motion target point, stores position data

3) Speed moving speed, units: %, mm/sec, cm/min…

4) CNT turning radius, FINE, CNT50, CNT100…

5) ACC100 additional instruction, not displayed if not added.

ABB

MoveL ToPoint, Speed, Zone, Tool;

1) MoveL instruction code

2) ToPoint motion target point, stores position data

3) Speed moving speed, unit: mm/s

4) Zone turning radius, FINE, Z50, Z100…

5) Tool tool number

Summary: The motion instructions of the two robots are roughly the same, with only minor differences, such as speed units. The ABB instruction shows a tool number, while FANUC’s is hidden…

I/O Control Instructions

DO Signal Set/Reset

ABB: set Do1/Reset Do1 or SetDO Do1,1/SetDO Do1,0

FANUC: DO[1]=ON/DO[1]=OFF

Output Pulse Signal

ABB: PulseDO\PLength:=2, Do1;

FANUC: DO[1]=Pulse, 2

Process Control Instructions

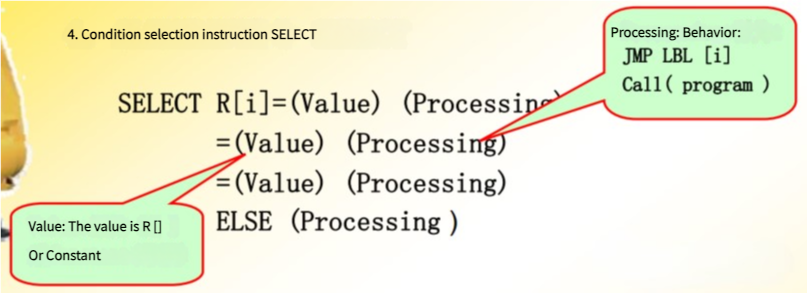

Fanuc SELECT instruction is consistent with ABB Test instruction

Fanuc IF instruction is consistent with ABB compact IF instruction, a compact conditional statement.

Jump Label Instruction

ABB: GoTo/LABEL

FANUC: JMP/LBL

Call Instruction

ABB: ProcCall

FANUC: CALL

Timing Instruction

ABB: clkstart clock1/clkstop clock1

FANUC: TIMER[1]=START/TIMER[1]=STOP

In the dynamic field of robotics, FANUC and ABB are two of the leading brands that have shaped the industry with their innovative and efficient robotic solutions. While both brands offer robust and precise robots, their operation and programming methods, although fundamentally similar, exhibit distinct characteristics that can be crucial for users to understand.

Robots from FANUC and ABB are widely used in various industries, including manufacturing, automotive, and electronics, for tasks such as assembly, material handling, and welding. Despite the differences in their programming languages and operational interfaces, the core functionalities of their programming instructions are often aligned to ensure smooth operation and control.

This introductory comparison of FANUC and ABB robot operations highlights the commonalities and differences in their programming instructions. Understanding these nuances is essential for operators and programmers who work with both types of robots, allowing for more efficient and effective robot utilization. As the robotics industry continues to evolve, the ability to navigate these differences will remain a valuable skill in the field.

Robotics is revolutionizing the way we approach manufacturing and automation. FANUC, as a leading brand in the industry, offers a range of robots that are known for their precision and reliability. Whether you are new to the world of FANUC robotics or looking to expand your knowledge, this beginner’s guide will provide you with the foundational knowledge needed to operate FANUC robots with confidence.

Understanding FANUC Robots

FANUC robots are widely used in various sectors, including automotive manufacturing, electronics assembly, and metalworking. They are designed to handle complex tasks with high accuracy and repeatability, making them a favorite among industries that demand high standards of quality and efficiency.

The world of FANUC robotics offers a wealth of opportunities for those looking to delve into the field of automation. This beginner’s guide serves as a starting point, equipping you with the necessary knowledge to operate FANUC robots effectively. As you progress, remember that practice, patience, and continuous learning are key to mastering the art of robotics.