Flexible Cables: The Versatility in Industrial Connectivity

Flexible cables are the backbone of many industrial applications, providing the necessary flexibility and durability required in dynamic environments. These cables are designed to withstand frequent movement, and repeated flexing while maintaining the integrity of electrical connections. They play a crucial role in a wide array of industries, from automation and robotics to stage lighting and heavy machinery.

Overview of Flexible Cables

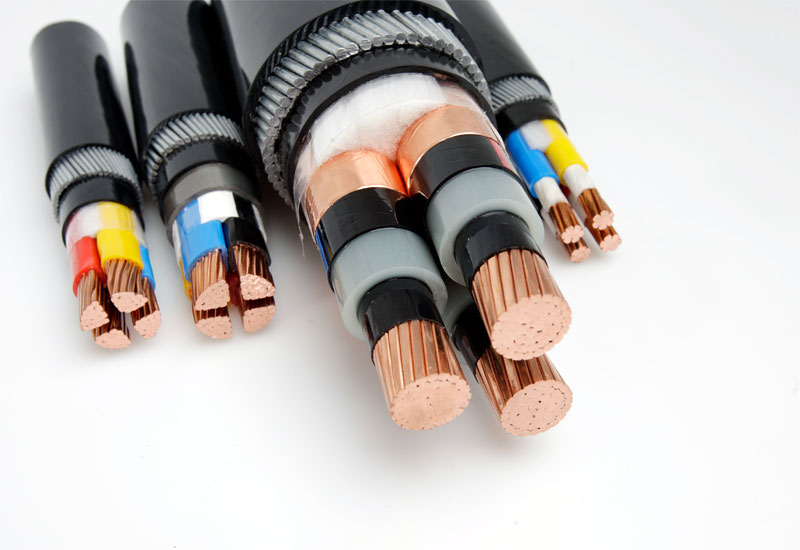

Flexible cables are engineered to provide a balance between flexibility and electrical performance. They are constructed with stranded conductors, which allow the cable to bend without breaking the internal wiring. The conductors are insulated with flexible materials and often protected by a flexible outer jacket, making them resistant to abrasion, oil, and certain chemicals.

Key Features of Flexible Cables

1. Stranded Conductors

The use of stranded conductors within flexible cables allows for excellent flexibility, reducing the risk of wire breakage due to repetitive motion.

2. Flexible Insulation

Flexible insulation materials, such as PVC or rubber, are used to coat the conductors, providing protection against electrical leakage and environmental factors.

3. Abrasion-Resistant Jacket

A robust outer jacket made from materials like polyurethane or nylon ensures the cable’s durability in abrasive conditions and resists wear and tear.

4. Multi-Flexibility

Some flexible cables are designed to be highly flexible, allowing for use in applications where the cable may be frequently moved or twisted.

Types of Flexible Cables

1. Multi-Conductor Flexible Cables

These cables contain multiple insulated conductors within a common jacket, suitable for applications requiring multiple electrical paths.

2. Shielded Flexible Cables

Shielded flexible cables offer protection against electromagnetic interference (EMI), making them ideal for use in environments with high electrical noise.

3. High-Temperature Flexible Cables

Designed for use in high-temperature environments, these cables can withstand continuous exposure to heat without degrading.

4. Extra-Flexible Cables

Extra-flexible cables are built to handle the most demanding conditions, including tight bending radii and constant flexing.

Considerations for Selecting Flexible Cables

When selecting flexible cables, consider the following factors:

1. Flex-Life

Understand the flex-life of the cable, which is the number of bends it can withstand before failure.

2. Temperature Range

Choose a cable with a temperature range that suits the operating environment, from low to high temperatures.

3. Chemical and Abrasion Resistance

Select cables with the appropriate resistance to chemicals and abrasion if they will be exposed to harsh substances or physical stress.

4. Cable Size and Weight

Consider the size and weight of the cable, as lighter and thinner cables may be preferable for applications where the cable is frequently moved.

Conclusion

Flexible cables are indispensable in industries where movement and flexibility are required. By selecting the right type of flexible cable based on the specific needs of your application, you can ensure reliable performance and longevity in even the most demanding conditions. As technology advances, the development of more robust and flexible cables continues to expand the possibilities of what can be achieved in dynamic industrial settings.

Pingback: How to Choose Industrial Robot Wire Harnesses