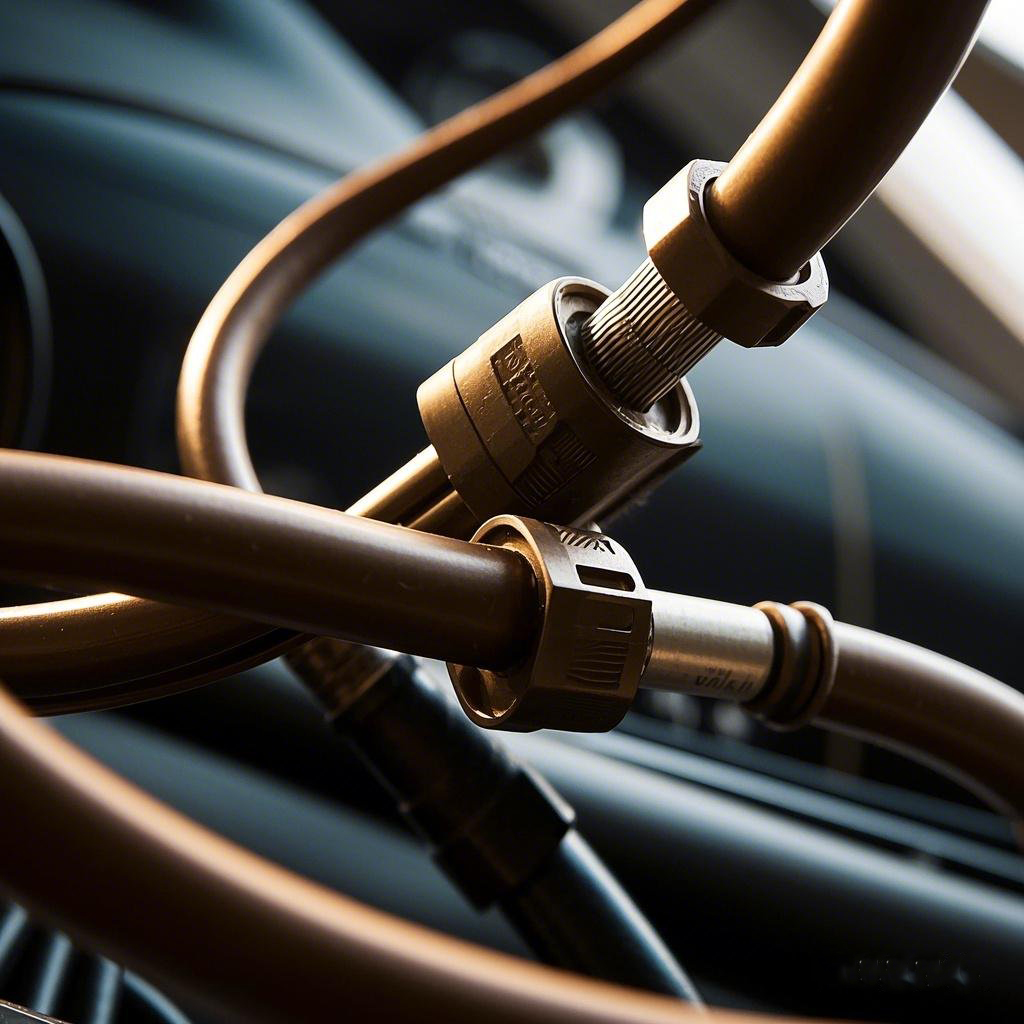

When it comes to ensuring the proper functioning of electrical systems in industrial machinery or robotics, one of the most crucial components is the wiring harness. A wiring harness is responsible for organizing and protecting the electrical cables and wires that connect different parts of a machine, ensuring efficient power transmission and safety. However, choosing the right wiring harness can be a daunting task, especially for those new to industrial machinery or robotics. In this article, we will guide you through the essential factors to consider when selecting a wiring harness for your needs.

1. Understand the Purpose of a Wiring Harness

Before diving into specifications, it’s essential to first understand what a wiring harness does. A wiring harness, sometimes referred to as a cable assembly, consolidates and organizes all the wires into a single, streamlined unit. It ensures that electrical signals and power can be transferred from one component to another without the risk of short circuits, tangling, or damage. For industrial robots, the wiring harness connects sensors, motors, controllers, and power supplies.

2. Identify the Type of Application

Wiring harnesses vary depending on the industry and application. Whether you’re looking for a wiring harness for a robot, machine tool, automotive, or any other type of electrical system, understanding the application will help you choose the right one. For example:

- Industrial Robots: Wiring harnesses for robots need to be flexible and durable to withstand the constant movement and stress in robotic arms.

- Automotive: Automotive wiring harnesses are designed to handle vibrations, temperature fluctuations, and moisture.

- Heavy Machinery: Wiring harnesses used in construction or mining equipment must be designed to endure harsh conditions, including dust, dirt, and extreme temperatures.

3. Consider the Material and Insulation

The material of the wires and the insulation surrounding them are critical factors in ensuring the longevity and performance of the wiring harness. Depending on the application, the wires may be made from materials like copper or aluminum, and the insulation could be made from PVC, Teflon, or silicone.

- Copper is a common choice due to its excellent conductivity.

- Aluminum is a lighter, cost-effective alternative but has lower conductivity than copper.

- Insulation protects the wiring from environmental factors like moisture, heat, or abrasion. Make sure the insulation material matches the specific needs of your application.

4. Evaluate the Environmental Conditions

Wiring harnesses must be able to perform in the specific environmental conditions where they will be used. For example, if your machinery will be exposed to extreme heat, cold, moisture, or chemicals, you need to choose a wiring harness designed to withstand those conditions. The wiring harness should be durable enough to resist the following:

- Temperature Variations: Ensure the materials can handle temperature extremes.

- Moisture: Waterproof or water-resistant harnesses are necessary in environments where there is a high level of moisture or exposure to water.

- Chemical Exposure: Harsh chemicals or oils can degrade the wires or insulation, so choose materials that offer resistance to such elements.

5. Size and Configuration

The size and configuration of a wiring harness are critical to ensure a proper fit and efficient routing within your machinery. A well-designed wiring harness should be easy to install and route through tight spaces. Consider factors like the number of wires, the gauge of the wires, and the length needed for the specific application. Custom wiring harnesses can be designed to fit the unique requirements of your equipment, ensuring that the wires are not too short or too long, which could cause inefficiencies or damage.

6. Compatibility with Connectors

Another important factor is the compatibility of the wiring harness with the connectors that will be used to link various components of the system. Ensure the wiring harness connectors are compatible with the connectors on your robot, machine, or electrical system. A mismatch in connectors can lead to poor connections, electrical failures, or even safety hazards.

7. Durability and Reliability

For industries that rely on heavy machinery and robots, the reliability of a wiring harness is crucial. Opt for a high-quality wiring harness that is durable and capable of withstanding years of heavy use. Some wiring harnesses are designed to be shockproof or vibration-resistant, making them ideal for machines in motion.

8. Customization Options

Not all wiring harnesses are “one-size-fits-all.” Depending on your specific needs, you may want to work with a manufacturer that offers custom wiring harnesses. A custom harness ensures that your wiring system is tailored to your machine’s exact specifications, increasing both the performance and longevity of your equipment.

9. Certifications and Standards

Make sure the wiring harness you choose complies with relevant industry standards and certifications. This can include ISO certifications or compliance with safety standards such as UL (Underwriters Laboratories) or CE (Conformité Européenne). These certifications ensure that the wiring harness meets the highest quality, safety, and performance standards.

10. Cost vs. Quality

While it’s tempting to go for the cheapest option available, it’s important to remember that the quality of a wiring harness plays a significant role in the safety, performance, and longevity of your machinery. In some cases, investing in a high-quality wiring harness will save you money in the long run by preventing breakdowns and minimizing the need for repairs.

Conclusion

Choosing the right wiring harness for your industrial robot, machinery, or any other application involves careful consideration of the materials, environmental factors, and specific requirements of your equipment. By understanding the factors discussed in this article, you can make a well-informed decision that will improve the efficiency, safety, and longevity of your machinery. Whether you need a standard or customized solution, ensuring the correct wiring harness is an investment in the future of your operations.